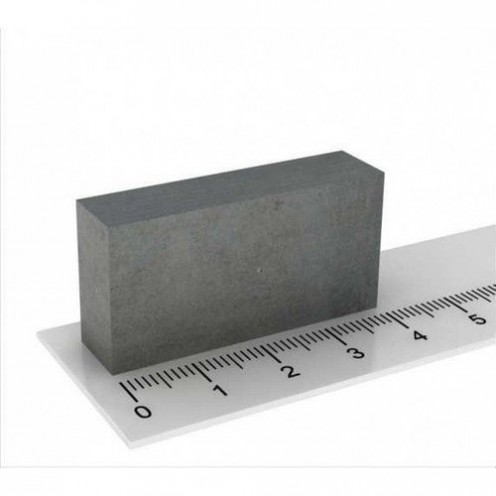

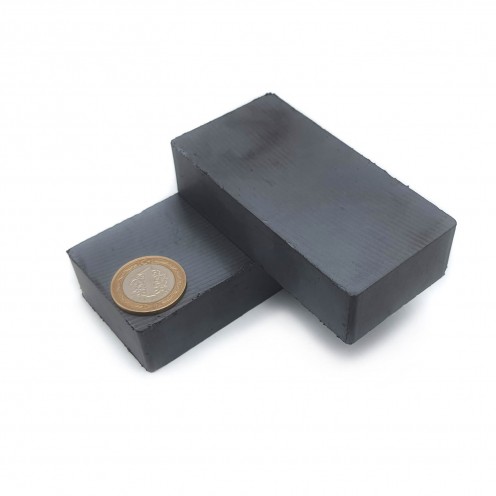

Square Rectangular Ferrite Magnets

- 25 Adet 56.10 TL

- 100 Adet 49.50 TL

- 500 Adet 42.90 TL

- 50 Adet 8.46 TL

- 250 Adet 7.52 TL

- 1000 Adet 6.58 TL

- 50 Adet 9.56 TL

- 250 Adet 8.50 TL

- 1000 Adet 7.43 TL

- 50 Adet 12.74 TL

- 250 Adet 11.33 TL

- 1000 Adet 9.91 TL

- 50 Adet 5.40 TL

- 250 Adet 4.80 TL

- 1000 Adet 4.20 TL

- 50 Adet 8.97 TL

- 250 Adet 7.98 TL

- 1000 Adet 6.98 TL

- 10 Adet 109.65 TL

- 50 Adet 96.75 TL

- 250 Adet 83.85 TL

- 25 Adet 90.78 TL

- 100 Adet 80.10 TL

- 500 Adet 69.42 TL

- 10 Adet 186.15 TL

- 50 Adet 164.25 TL

- 250 Adet 142.35 TL

- 10 Adet 190.13 TL

- 50 Adet 167.76 TL

- 250 Adet 145.39 TL

- 10 Adet 203.15 TL

- 50 Adet 179.25 TL

- 250 Adet 155.35 TL

- 5 Adet 277.20 TL

- 25 Adet 246.40 TL

- 100 Adet 215.60 TL

- 5 Adet 269.10 TL

- 25 Adet 239.20 TL

- 100 Adet 209.30 TL

Rectangular Ferrite (Ceramic) Magnets

Ferrite ceramic magnets are manufactured using powder metallurgy techniques. The oxide sintering process used in the production of these magnets is carried out with advanced microstructure control technology. For this reason, they are also known as core magnets. With excellent practical properties, ferrite ceramic magnets perform much better than metallic magnets (Al-Ni-Co). These products, which can be mass produced at high rates, provide high performance.

Ceramic magnets, which are used in many applications from refrigerator magnets to small electric motors and speakers, are one of the permanent magnet types. Ferrite magnets can be magnetized in any direction and are isotropic, meaning their magnetic properties are the same in all directions. However, there are also ferrite magnets that are anisotropic and have a specific direction of magnetization, which makes them have stronger magnetic properties.

Anisotropic ferrites have the strongest magnetic properties in a given direction and are stronger than isotropic ferrite magnets. Soft ferrites, on the other hand, have low coercivity and can easily change their magnetization, making them ideal materials that act as conductors of magnetic fields. The production temperature of ferrite magnets is between 1000 and 1350 degrees Celsius. However, they are less strong and durable than neodymium magnets.