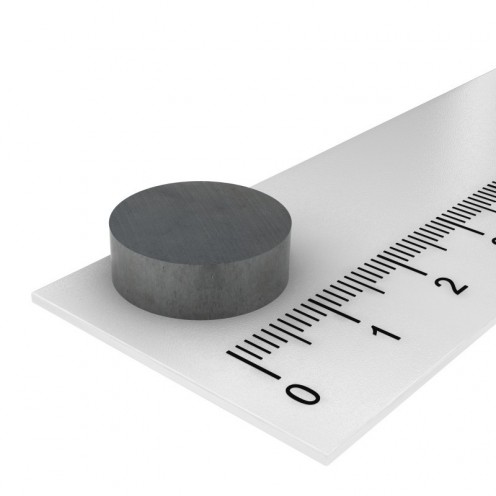

Round Ferrite Magnets

- 500 Adet 2.11 TL

- 2500 Adet 1.92 TL

- 10000 Adet 1.68 TL

- 500 Adet 3.17 TL

- 2500 Adet 2.88 TL

- 10000 Adet 2.52 TL

- 500 Adet 1.48 TL

- 2500 Adet 1.34 TL

- 10000 Adet 1.18 TL

- 500 Adet 1.25 TL

- 2500 Adet 1.14 TL

- 10000 Adet 0.99 TL

- 500 Adet 1.94 TL

- 2500 Adet 1.76 TL

- 10000 Adet 1.54 TL

- 500 Adet 0.79 TL

- 2500 Adet 0.72 TL

- 10000 Adet 0.63 TL

- 500 Adet 1.32 TL

- 2500 Adet 1.20 TL

- 10000 Adet 1.05 TL

- 500 Adet 0.53 TL

- 2500 Adet 0.48 TL

- 10000 Adet 0.42 TL

- 500 Adet 1.06 TL

- 2500 Adet 0.96 TL

- 10000 Adet 0.84 TL

- 50 Adet 7.56 TL

- 250 Adet 6.72 TL

- 1000 Adet 5.88 TL

- 50 Adet 10.80 TL

- 250 Adet 9.60 TL

- 1000 Adet 8.40 TL

Round Ferrite Magnets

Ferrite magnets are produced by calcining a mixture of strontium carbonate and iron oxide. This is done in order to form a metallic oxide, resulting in magnets with excellent temperature stability, with superior corrosion resistance and can be used up to 250 degrees Celsius. Ferrite magnets are a cost-effective solution for those who need to coat a large surface area and have excellent resistance to high temperatures. They are often used in refrigerator magnets and high temperature applications.

Round ferrite magnets are sintered permanent magnets composed of barium or strontium ferrite. Ferrite magnets are made from SrO or BaO and Fe2O3 by ceramic processing technology and are produced in various grades such as Y10T, Y30, Y35, C5, C8. They require special processing techniques because they are very hard and brittle. Ferrite magnets are available in round, rectangular, hollow, plate and block types. They can be magnetized in any direction and have the advantage of high coercivity and low cost.

Such products have excellent corrosion resistance, do not require any surface treatment and can be used in a variety of permanent applications. Also known as ceramic, coal and oxide magnets, these ferrite products are permanent and artificial. However, they are not suitable for impact and cutting due to their hard structure.