Demagnetizer - Demagnetizing

Demagnetizer Types and Prices

Demagnetizers are used to clean the magnetization layer that forms on materials over time. Among the products in the field of magnets and magnetic systems, demagnetizers are among the most needed and popular products. There are various reasons for the magnetization of materials; mechanical impact, exposure to static electric charge, externally applied electromagnetic field or material exposed to natural magnetization are some of these reasons.

Magnetization - Demagnetized Systems

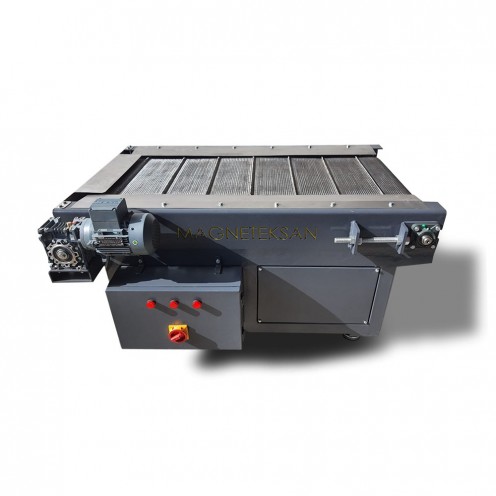

You can find detailed information about demagnetizers used for demagnetizing, i.e. demagnetizing, on our website. Models diversified according to different usage areas such as handheld and machine type are offered for sale to meet the needs of our customers. Demagnetizers suitable for every need are available on our website with quality and affordable product options. Demagnetizers, which eliminate residual magnetization on the material, can be specially produced according to the desired size and dimensions. They are especially actively used on steel saws, machine parts, thin molds and knife materials.

By examining the demagnetizers on our site, you can quickly order the model suitable for your needs. It is very easy to reach the product models in different types according to customer requests with a single click. Various demagnetizer models, including tunnel type, plate type and hand type, can be designed in requested dimensions and special sizes. You can place your order immediately by choosing the most suitable demagnetizer for your needs.